Smart factory! Intelligent manufacturing systems (LBYMF4D & MFELEC2)

TARGET AUDIENCE: Students, Academics, Industry Professionals, Employers, and Tech Enthusiasts

OVERVIEW: The manufacturing scene is evolving fast. There are many technologies that are being utilized in the field and frankly, no time to catch up. In the Philippines alone, I have seen upskilling for workers for Industry 4.0 in big companies to catch up with the demand and expectations that the current world wants for their plant engineers. For me, staying ahead and learning these topics are essential if I want to enter this type of work in the future. Below is my learnings that I got from my classes in terms of practical skills in data communication, IoT integration, and system automation through the use of microcontroller like ESP32 and Raspberry Pi.

LECTURE:

The lecture was fun. I got to really hone my skills this time around with the several exercises that was given to use while giving nod to the different courses that I had in previous term. It challenges me to do exercises on industrial electronics, instruction lists and raspberry pi basics! Particularly, I got to learn the following:

Ladder Logic and Instruction Lists:

- Reviewed LLDs and created corresponding

instruction lists (IL)equations in MSExcel. - Developed truth tables based on logic implemented through IL and

logic ladder diagrams. - Simulated LLDs in Festo FluidSim.

- Implemented

logic functionsusing IF statements in MSExcel.

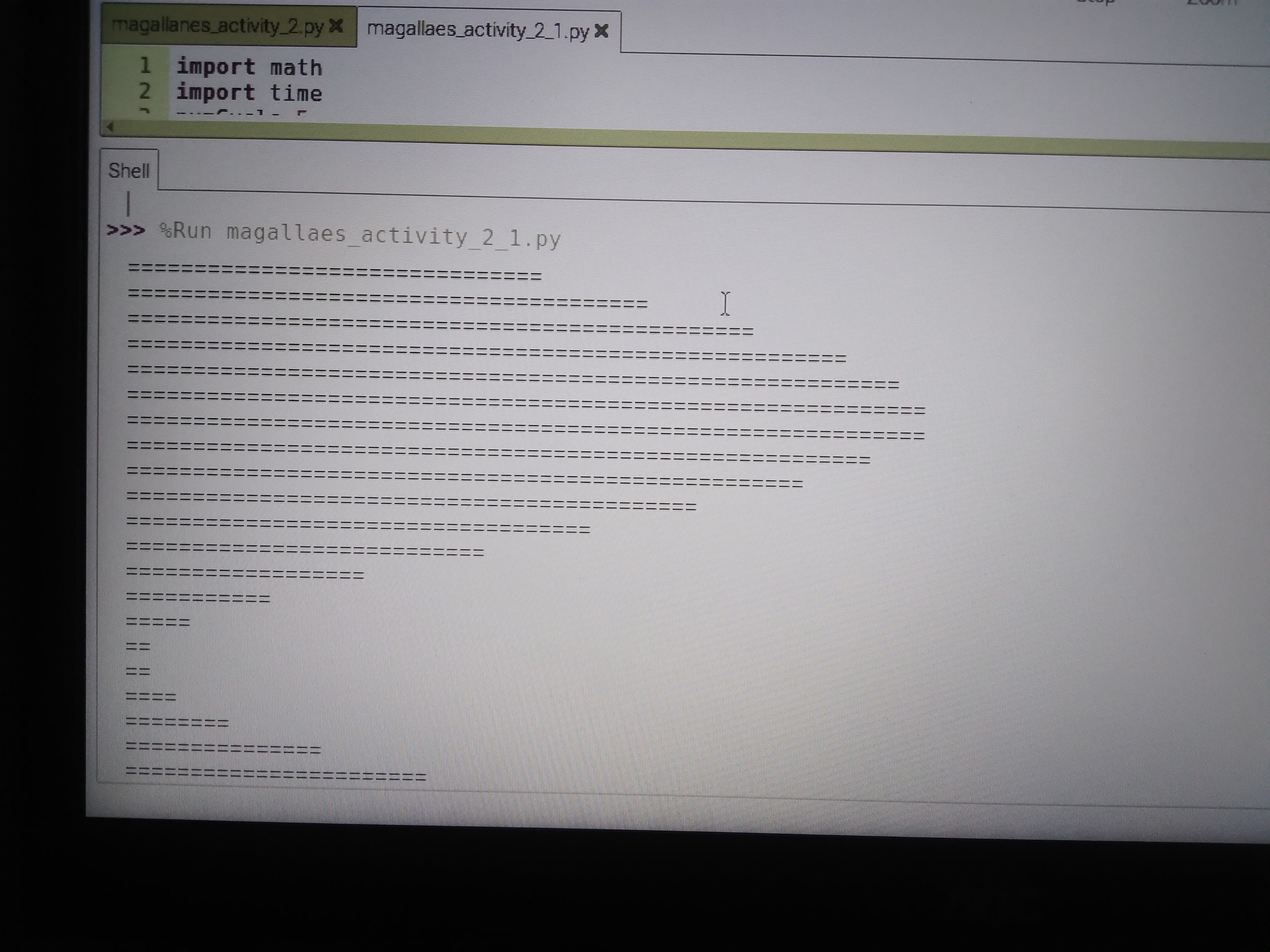

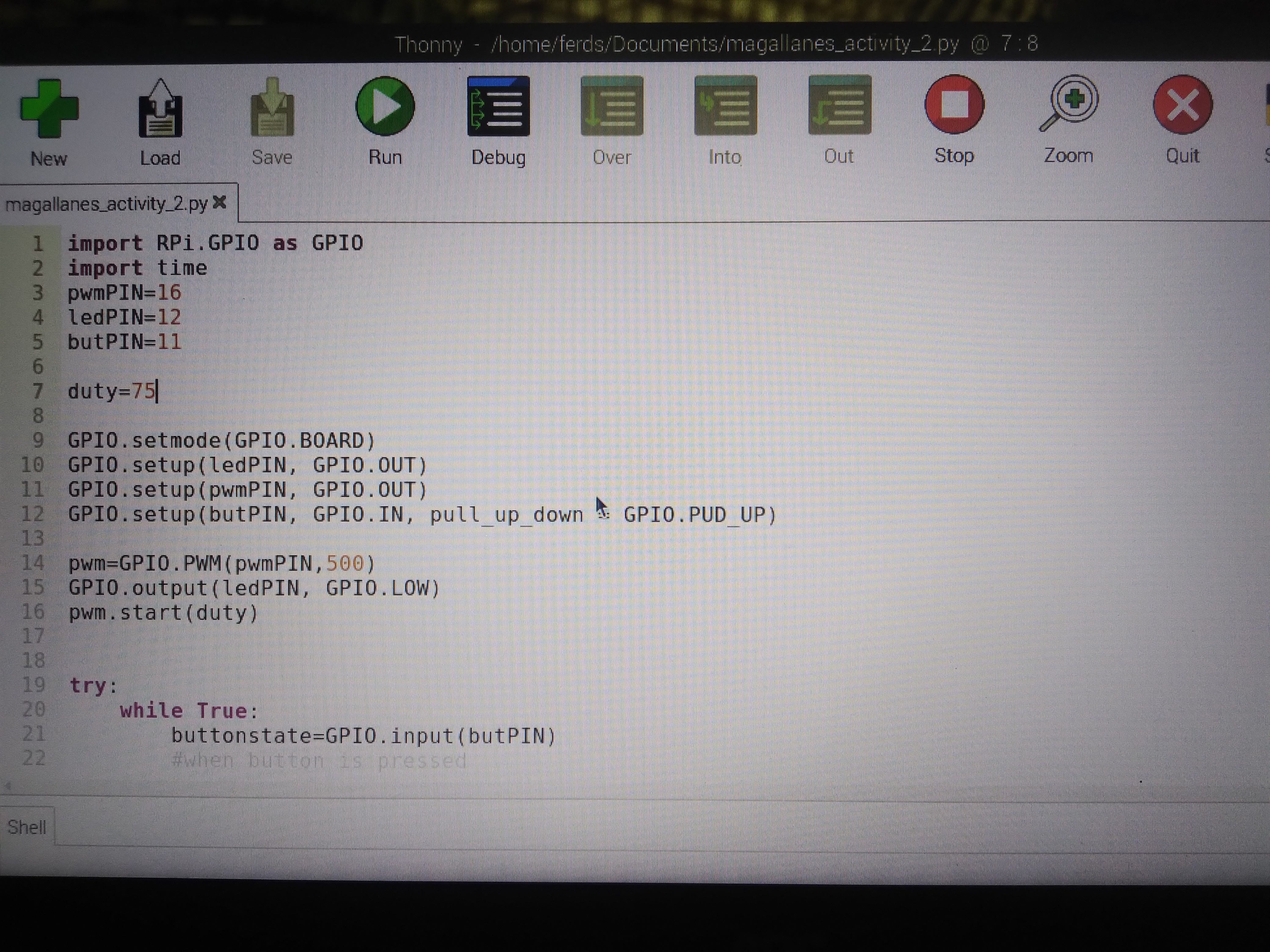

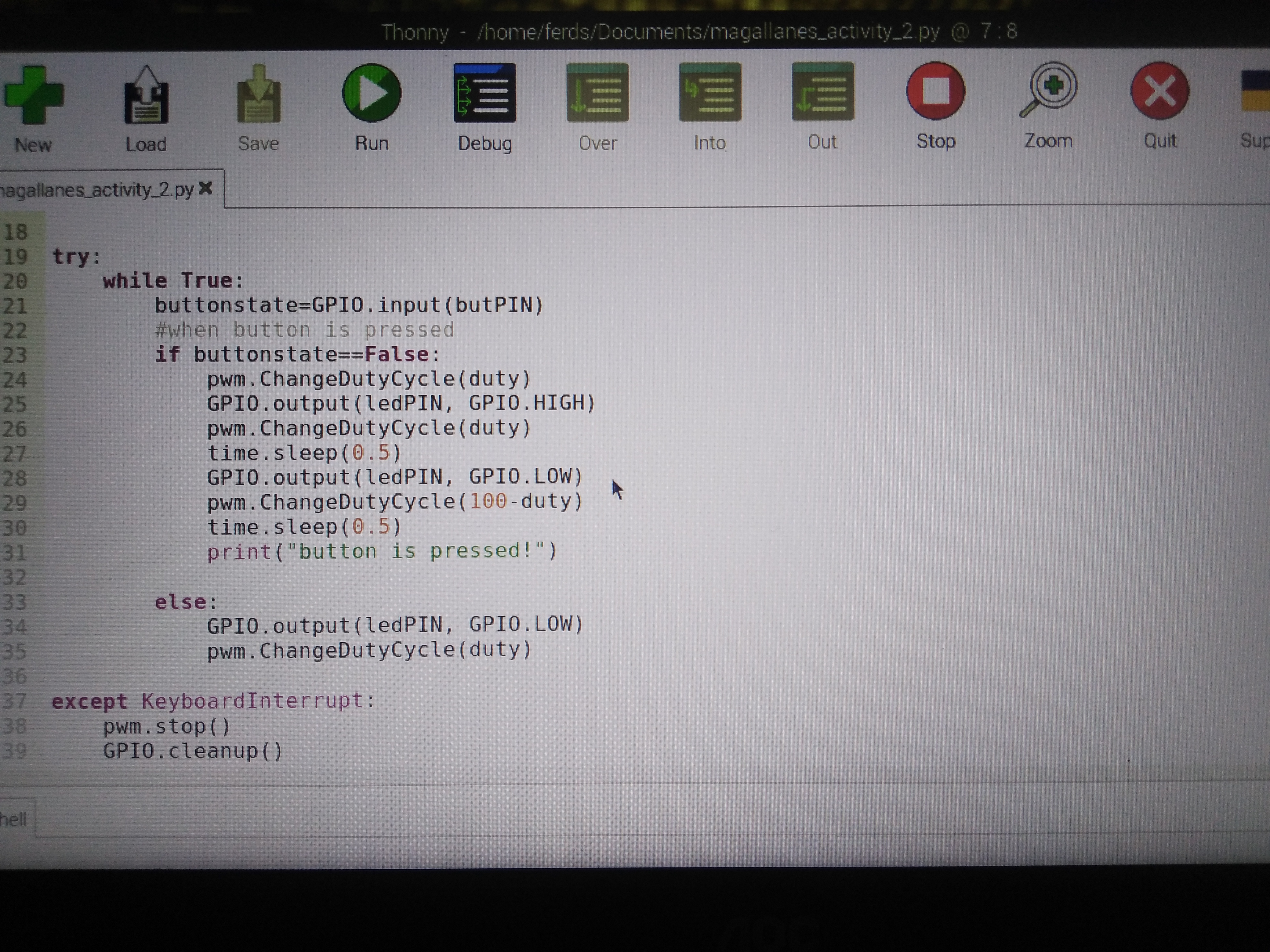

Raspberry Pi Basics:

- Utilized GPIO to drive outputs and read inputs, correcting errors in provided code.

- Created programs for LEDs and pushbuttons.

- Developed functions for measuring distance using an

Ultrasonic Sensor (HC-SR04). - Implemented a Tkinter GUI module.

- Configured port forwarding on a

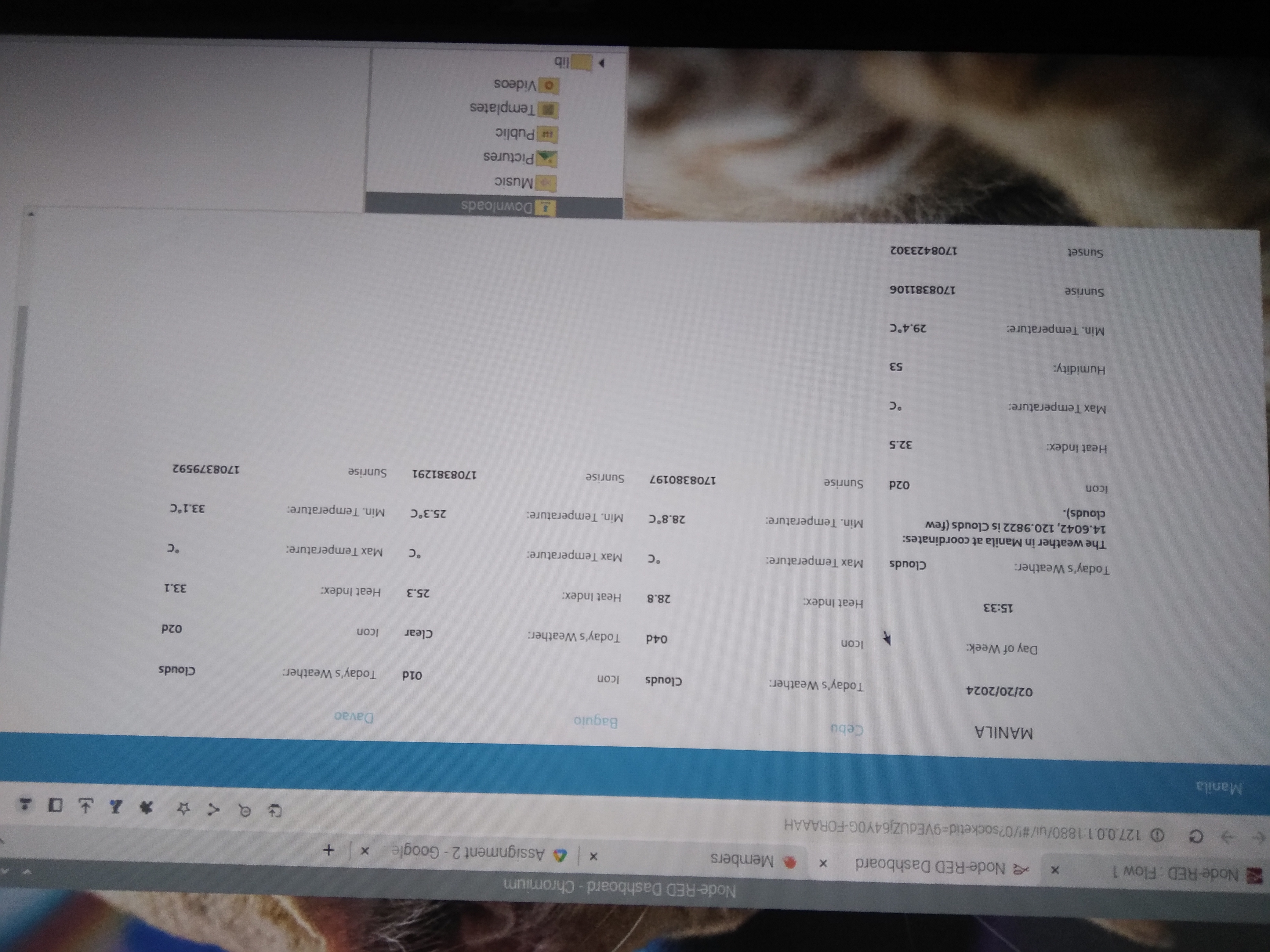

Huawei OptiXstar HG8145X6 routerto create anSSH server. - Accessed the

SSH servervia PuTTY from a separate device not connected to the Raspberry Pi’s local network. - Attempted to install Node-Red and use Arduino IoT Cloud

Face Detection:

- Integrated a

USB webcamwith Raspberry Pi. - Utilized

RealVNCfor remote access. - Installed the

OpenCVlibrary. - Ran

face and eye detection programsusinghaarcascadeXML files

Below is a consolidated document of the outputs that I did for this lecture.

LABORATORY:

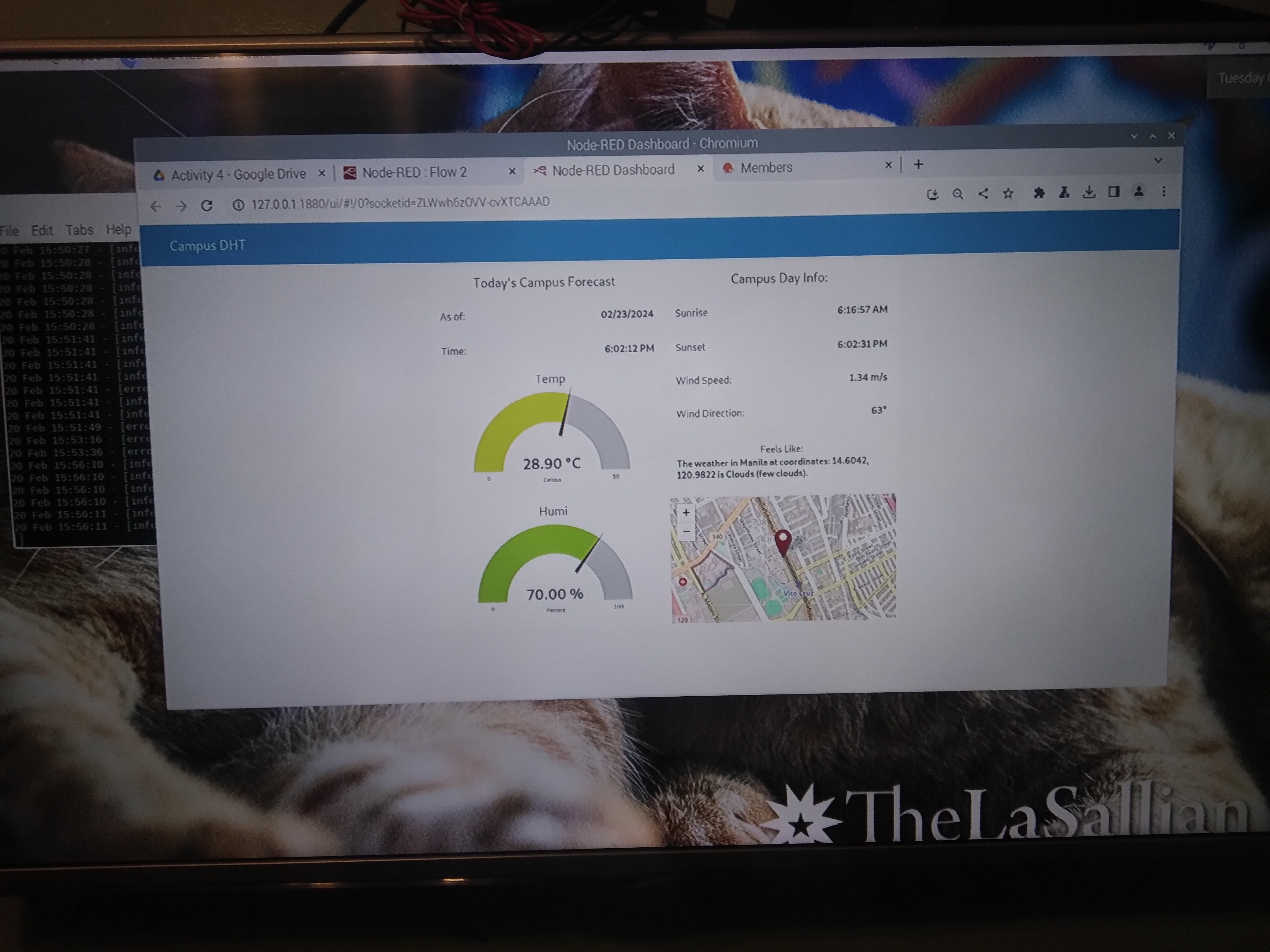

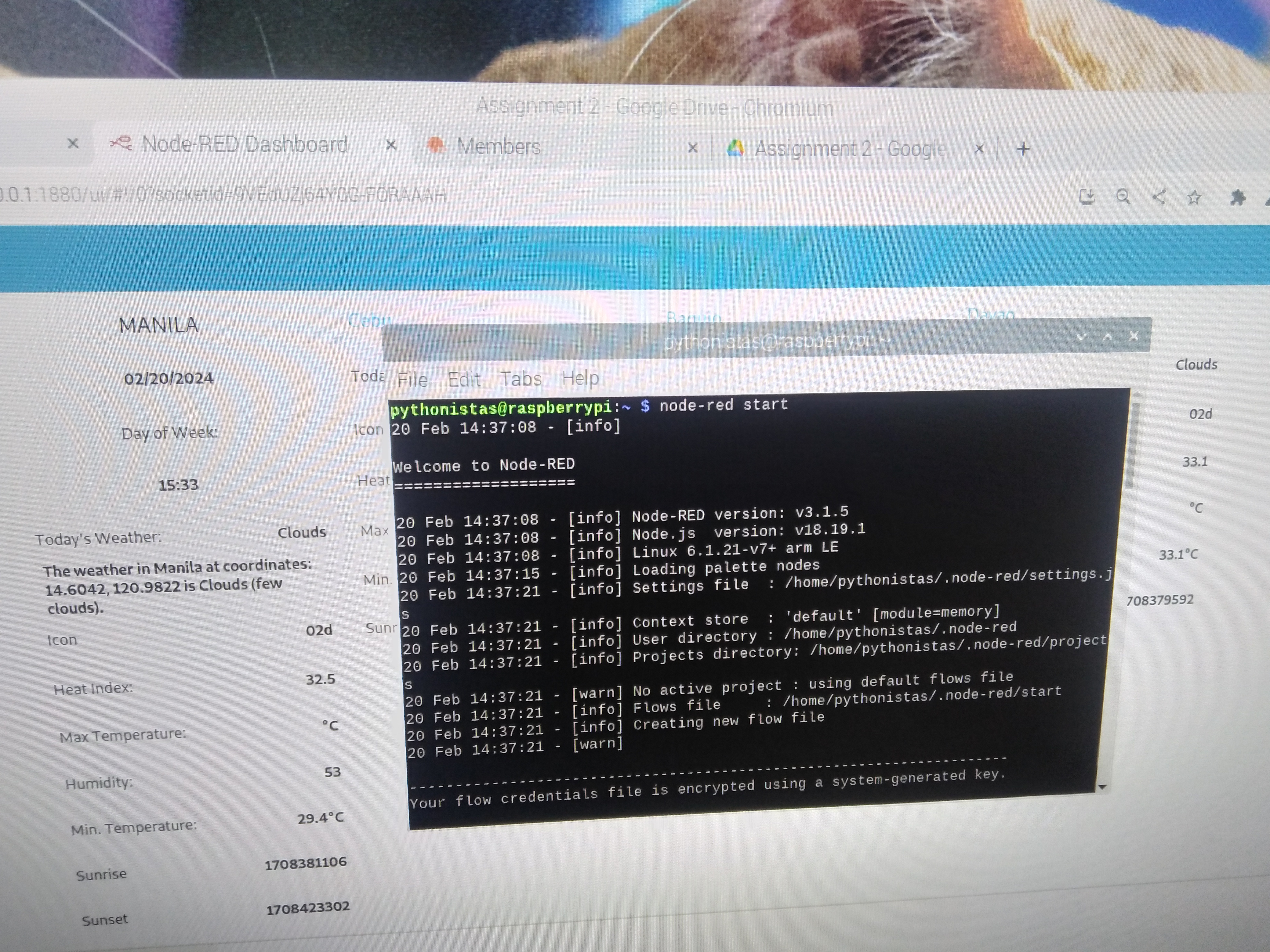

The laboratory covers the use of microcontroller for IoT and automation. We got to provide sensor integration and cloud connectivity for real-time monitoring using two platforms (Arduino IoT Cloud, ThingsSpeak). The concepts that the class provide is an introductory on using these types of peripherals for various applications. Here are some of things that I have done knowing this :))

Microcomputers for Control and Edge Processing

Raspberry Pi (RPI)

- OS setup and configuration for standalone operation.

- GPIO programming to control

actuators(servo motors, pushbuttons). - Python programming for

automation sequences(servo position cycles). -

Skill relevance: Raspberry Pi acts as anedge device. in Intelligent Manufacturing Systems (IMS), handling local computation, machine control, and human-machine interfaces.

Sensor & Actuator Integration

- Practical experience in connecting and programming sensors:

-

DHT11→ humidity & temperature monitoring. -

LM35, pH sensor, Dissolved Oxygen sensor (proposed project)→ environmental monitoring for aquaculture.

-

- Actuators:

-

Servo motorsfor precise movement/feeding systems. -

LED indicatorsfor process signaling.

-

- Skill relevance: This is the core of cyber-physical systems, where machines perceive their environment and act intelligently.

IoT & Data Communication

- Hands-on with

serial data transmission, data cleaning, and visualization. - Implemented

real-time dashboards(via Arduino IoT Cloud / ThingSpeak). - Learned to troubleshoot

Wi-Fi, firewall, and data-transfer issues. - Skill relevance: These skills align with Industrial Internet of Things (IIoT), enabling remote monitoring and predictive maintenance.

Simulation & Visualization

-

VPythonfor simulating 3D environments and interactive displays. - Showcased

augmented reality conceptswhere virtual objects respond to real-world sensor inputs. - Skill relevance: Simulations and digital twins are increasingly used in smart manufacturing systems for design, testing, and operator guidance.

Systems Thinking & Project Integration

- Developed a capstone project:

Intelligent Aquaculture Feeder System.- Integrated sensors (temperature, dissolved oxygen, pH).

- Used

ESP32 + Raspberry Pi + Servo motorfor feeding automation. - Built a

cloud dashboardfor monitoring & control.

- Skill relevance: Demonstrates the ability to design end-to-end intelligent systems combining hardware, software, IoT, and automation.

The last part, I was able to present and showcase it in a IEEE conference, you may check it out on my publications section!!

REFLECTIONS: Overall, I learned a lot but I then realize that I’m barely scratching the surface on the amount of the technology and forward thinking applications that needs to be learned to stay ahead of the indsutry standards. Quite frankly, the world has changed indeed and it is not enough that I stay contented in the small wins that I have done in this course but also look ahead on what is needed for the job and the duty that it comes when i’m dealing with it in real-life.

There are so many things to explore and study that is why this is a continuous effort on my end if I want to become someone that can handle and contribute to industry 4.0 in the Philippines. These are merely the building blocks in smart factories, such as:

- Predictive maintenance (via sensors + analytics).

- Automated material handling (via robotics + IoT).

- Process monitoring dashboards (via ESP32/RPi cloud integration).

- Digital twins & simulations (via VPython/AR concepts).

The next step for me is to continue down this road and know that I will never to prepared for what comes next but 50% of the effort comes from showing up and doing the work if I want to be part of this exciting industry~!

Acknowledgements: Thank you doc Renann for the oppurtunity to publish our work to IEEE! sir sonjay for his guidance; Jaimie, Pat for being there 100% along the way for the project!

Enjoy Reading This Article?

Here are some more articles you might like to read next: